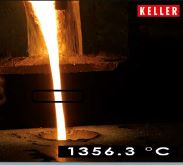

Hand-held pyrometer for non-wearing temperature measurement of liquid metal

Until recently, foundries and steel mills employed measuring rods to detect liquid metal temperature. With this method, a probe is immersed into the molten metal bath and must be replaced after every measurement. Not only do the running costs of these consumables contribute to a plant’s operating expenses – the immersion technique has other drawbacks as well. The accuracy of the data can vary greatly because the temperature is subject to the depth and location of the immersion. Besides that, temperature measurement is carried out at the ladle or furnace, prior to actual casting. The process temperature which is decisive for quality, however, is that of the metal just as it pours into the mould. Liquid metal that is too hot can damage the core. When the molten metal cools, its flow properties change as the liquid metal begins to solidify. The molten metal might not completely fill the mould cavity and lead to defects in the cast part. This is especially true with intricately shaped moulds and fine surface detail such as in investment casting.

To provide an alternative to immersion measurement in molten metal applications, KELLER MSR engineered CellaCast, a stationary infrared measuring system. CellaCast detects liquid metal temperature without contact or mechanical wear. The system captures the molten pour stream just as the mould is being filled. The system records a temperature for each pour and thus for each cast object. Since its market launch three years ago, CellaCast has been installed at numerous plants worldwide and proved its worth. As a response to customer demand, Keller MSR has now designed a portable version of CellaCast. As a hand-held device, CellaCast now offers enhanced versatility and is especially convenient with constantly varying pour streams such as in manual casting operations.

One of the challenges to non-contact temperature detection is the development of slag and oxide on the molten metal surface. Changes to the surface characteristics will change the radiation properties. When this is the case, a standard instrument will yield erroneous measurement data.

CellaCast PT 183 is unique in that is features a special analysis and filter function. The instrument recognizes the metal surface free of slag or oxide. It only factors in the infrared radiation captured from these pure areas to produce a highly accurate temperature reading.

Another technological innovation of CellaCast PT 183 is the rectangular measurement area. Because this feature is part of the optics, it is achieved without moving parts. Pyrometers commonly feature a circular target spot. Capturing the molten pour within the rectangular area greatly facilitates manual targeting from a distance. CellaCast has turned hand-held pyrometer measurement of molten metal into a truly feasible solution. As a dual-wavelength pyrometer, CellaCast permits a target object which is smaller than the measurement area; the pour stream does not need to fill the area but may move within it. This ensures that the molten stream is captured every time even when its position varies, such as when the angle of the pour changes.

Through-the-lens sighting and target spot indication within the viewfinder make it easy to focus on the hot metal target. The CellaCast PT 183 is infinitely adjustable to ensure superior precision across a wide focusing range from 0.4 m to infinity. An adjustable, integrated polarizing filter protects the eye. The ocular features widened interpupillary distance, making it suitable for users who wear glasses or a helmet. Because it measures at two different wavelengths, CellaCast yields very accurate temperature data even when dust or steam impair the line of sight.

Signal Attenuation Monitoring (SAM) is a function which identifies whether the amount of infrared energy detected is sufficient to produce reliable temperature data. If measurement is not possible because the pour stream diameter is too small, too far away, or there is too much steam or dust obstructing the sight path, SAM will prevent the pyrometer from generating a false temperature reading. A traffic light status indicator, integrated in the viewfinder, also tells the user when, under the existing conditions, the distance to the target will not permit temperature measurement.

Signal Attenuation Monitoring (SAM) is a function which identifies whether the amount of infrared energy detected is sufficient to produce reliable temperature data. If measurement is not possible because the pour stream diameter is too small, too far away, or there is too much steam or dust obstructing the sight path, SAM will prevent the pyrometer from generating a false temperature reading. A traffic light status indicator, integrated in the viewfinder, also tells the user when, under the existing conditions, the distance to the target will not permit temperature measurement.

Signal Attenuation Monitoring (SAM) is a function which identifies whether the amount of infrared energy detected is sufficient to produce reliable temperature data. If measurement is not possible because the pour stream diameter is too small, too far away, or there is too much steam or dust obstructing the sight path, SAM will prevent the pyrometer from generating a false temperature reading. A traffic light status indicator, integrated in the viewfinder, also tells the user when, under the existing conditions, the distance to the target will not permit temperature measurement.

For prolonged temperature data logging, the CellaCast PT 183 can be mounted on a tripod and the data to can be transmitted to a PC by the USB interface The CellaMevis software, which is supplied with the pyrometer, provides a graphic image of temperature over time and saves the temperature of each casting poured from a specific ladle. This affords in-depth analysis of the molten metal’s cooling behaviour and can indicate thermal fatigue of the refractory lining.

The CellaCast PT 183 measures temperatures from 650 °C to 1700 °C which covers the entire range of applications involving ferrous and non-ferrous melts at foundries and steel mills. These include the cupola furnace, forehearth, melting furnace, holding channel furnace, transport ladle and pouring ladle.

Summary:

CellaCast PT 183 has made it possible, for the first time ever, to check the temperature of each cast piece quickly and easily as the metal is being poured. CellaCast PT 183 can generate significant cost savings because expendable thermocouple tips become unnecessary. What’s more, Monitoring temperatures at the crucial moment as the molten metal enters the mould allows the operator to interrupt the production process immediately when limits have been violated. This measurement technique thus enables strict compliance with process requirements and will thus greatly reduce the amount of scrap produced.